| Model: | FMP200SC60-BE12-30 |

| Brand: | WORLDIA |

| Availability: | In stock,immediate despatch |

| Place of origin: | Beijing,China |

| Capacity(Monthly): | 1000PCS |

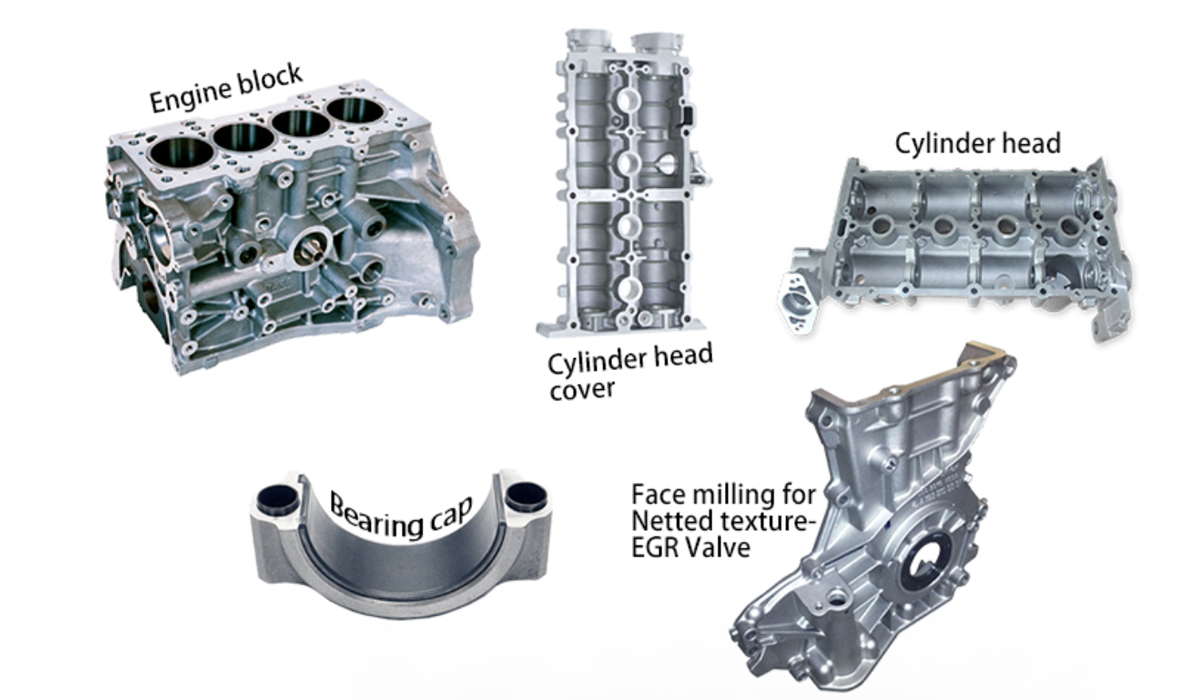

APPLICATIONS |

| WORLDIA PCD Indexable face milling with exclusive design has helped clients increase their capacity and reduce their tooling costs by allowing them to significantly increase speeds and feeds. |

Features |

PRODUCT USAGE |

| According to grain size and features of diamond,four types of PCD material, i.e PD01E / PD10E / PD32E / CVDD are listed as below. |

| P | ||||

| M | ||||

| K | ||||

| N | ● | ● | ● | ● |

| S | ||||

| H | ||||

| Material | PD01E | PD10E | PD32E | CVDD |

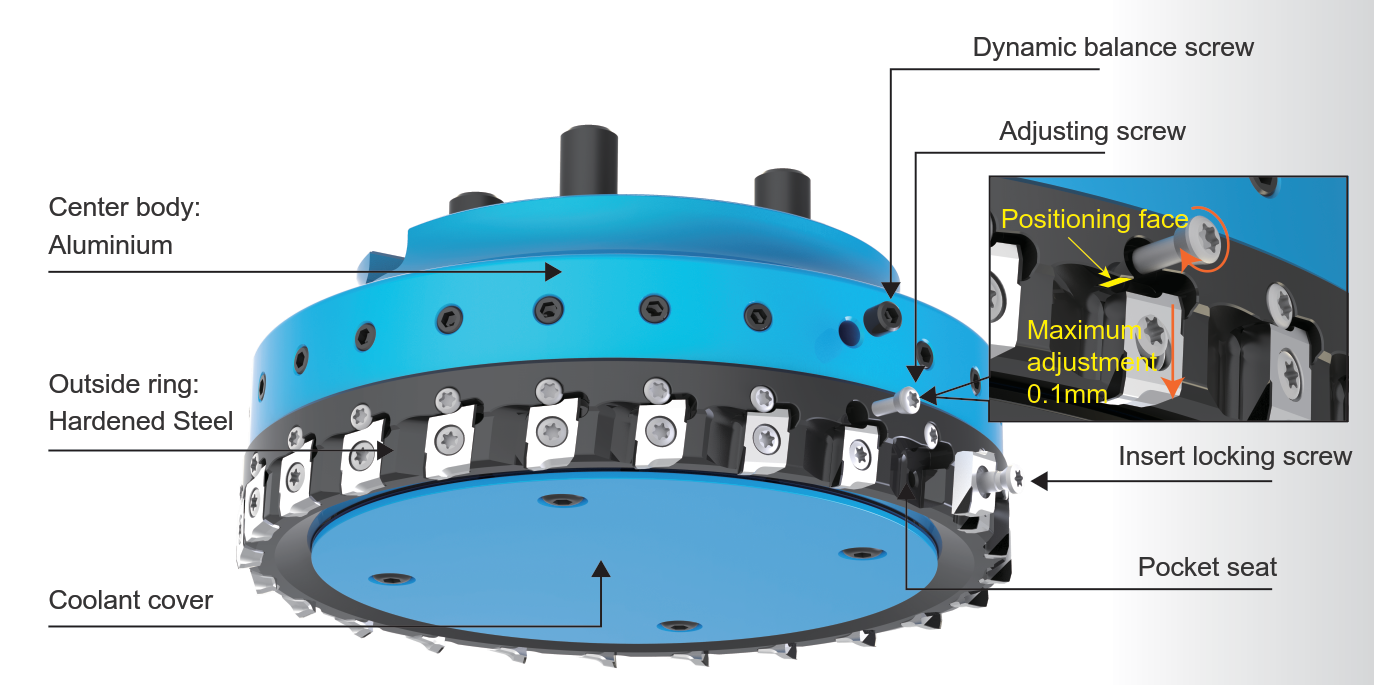

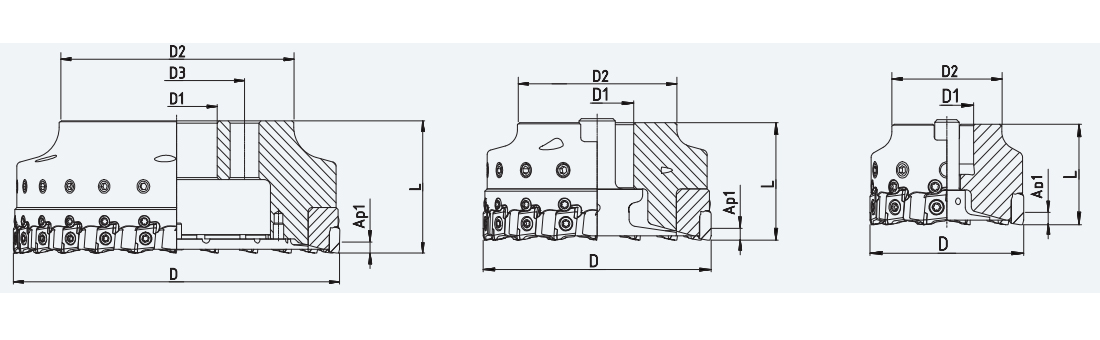

STRUCTURE DETAILS |

MATERIAL INTRODUCTION |

| Material | Grain size | Features | Application |

| PD01E | 10 | PD10E is the universal grade in the market. It's the first choice for many applications where agood balance of toughness and wear resistanceare required. | This grade is commonly used for non-ferrous finishing applications. Other successful applications include machining of wood, MDF, low-mediumcontent silicon aluminium alloys, carbide, hardrubber, graphite and so on. |

| PD32E | 2-30 | PD32E has a unique combination of wear resistance,edge strenth and edge quality. It contains a carefully sorted mix of micron diamond (between 2 - 30 μm). The combination of these particle sizes and a specifically developed high pressure sintering process produces a structure with extreme abrasion resistance and good thermal stability. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

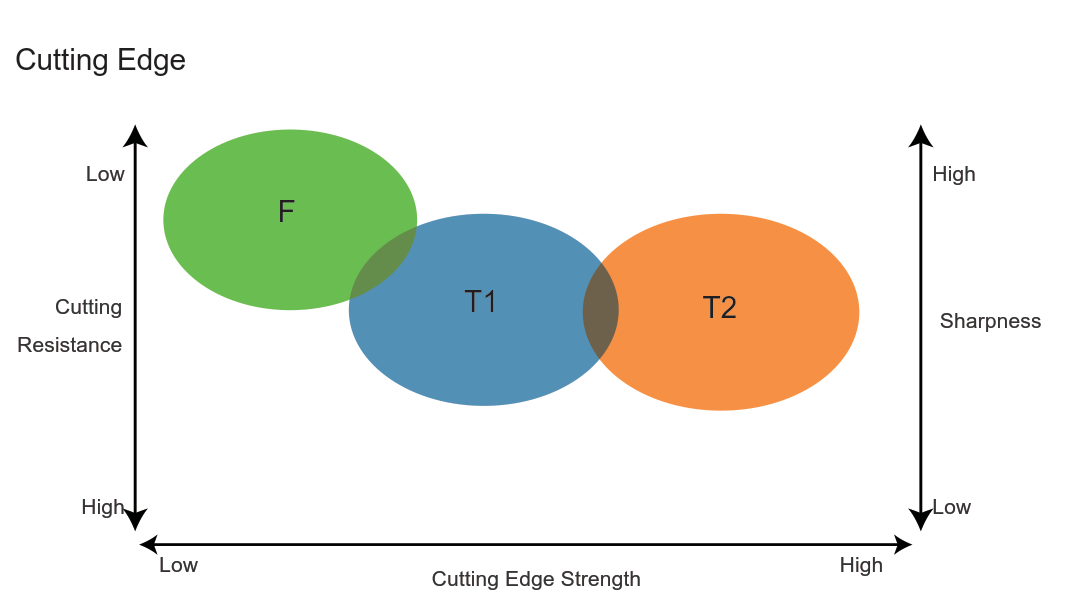

MATERIAL PERFORMANCE |

SPECIFICATIONS |

| D | D1 | D2 | D3 | L | Ap1 Max | Teeth | Weight | ||||

| Specification | System Code | mm | mm | mm | mm | mm | mm | Z | Kg | max RPM | Material |

| FMP040SA16-BE12-06 | 040401060013 | 40 | 16 | 36 | - | 40 | 11 | 6 | 0.36 | 40000 | Steel |

| FMP050SA22-BE12-08 | 040401060005 | 50 | 22 | 45 | - | 40 | 11 | 8 | 0.55 | 35100 | Steel |

| FMP063SA22-BE12-10 | 040401060006 | 63 | 22 | 45 | - | 40 | 11 | 10 | 0.75 | 30200 | Steel |

| FMP080SA27-BE12-12 | 040401060007 | 80 | 27 | 50 | - | 50 | 11 | 12 | 0.96 | 27500 | Steel-aluminium |

| FMP100SB32-BE12-16 | 040401060008 | 100 | 32 | 70 | - | 50 | 11 | 16 | 1.45 | 23800 | Steel-aluminium |

| FMP125SB40-BE12-20 | 040401060009 | 125 | 40 | 90 | - | 63 | 11 | 20 | 2.4 | 19100 | Steel-aluminium |

| FMP160SC40-BE12-24 | 040401060010 | 160 | 40 | 115 | 66.7 | 63 | 11 | 24 | 3 | 14900 | Steel-aluminium |

| FMP200SC60-BE12-30 | 040401060011 | 200 | 60 | 150 | 101.6 | 63 | 11 | 30 | 4.25 | 11900 | Steel-aluminium |

| FMP250SC60-BE12-36 | 040401060012 | 250 | 60 | 200 | 101.6 | 63 | 11 | 36 | 6.5 | 9550 | Steel-aluminium |

PROCESSING CASES |