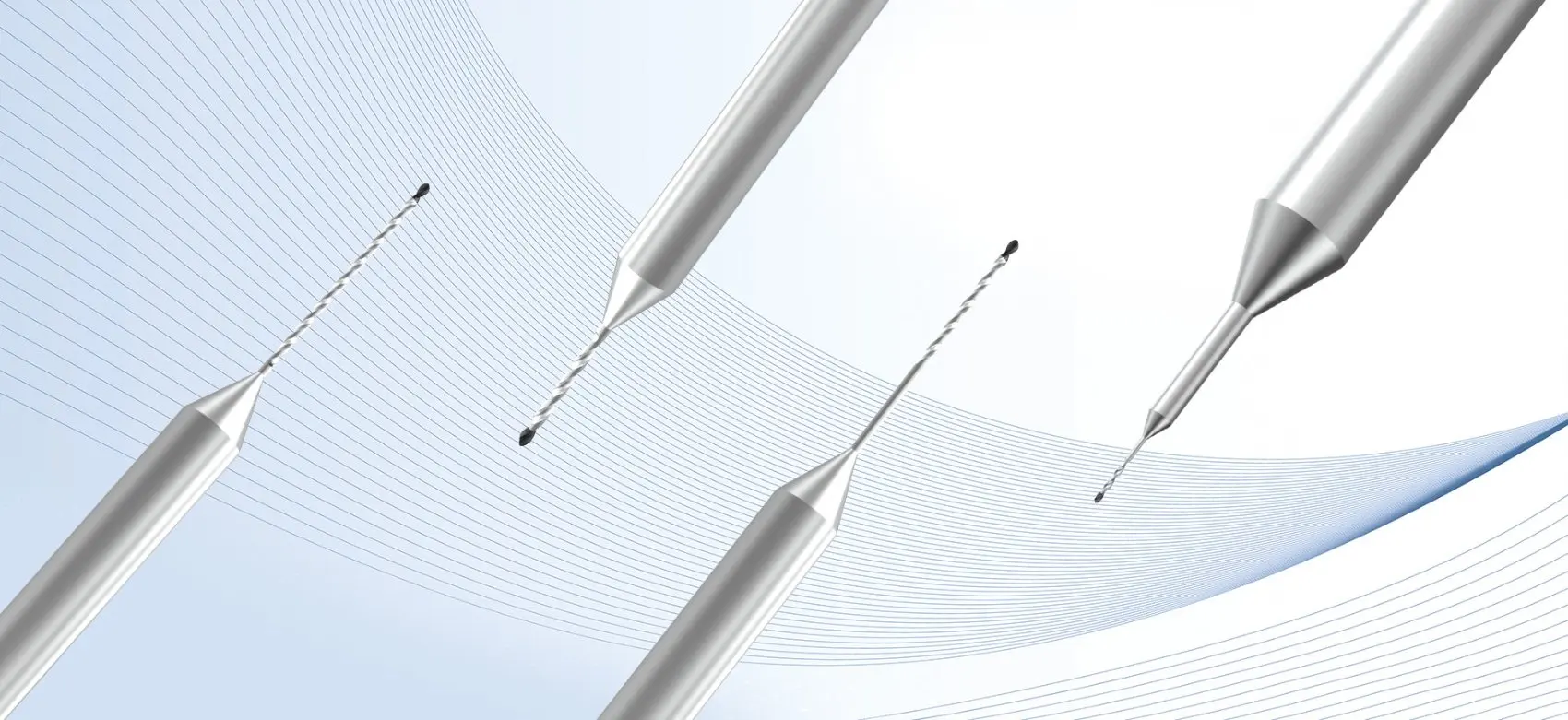

Tools with PCD, CVDD, PCBN and MCD

cutting edges

Solid and indexable carbide

tools

High-precision tools for

micro-machining

Accessories to connect our tools to your

machine

Regrinding and retipping

services

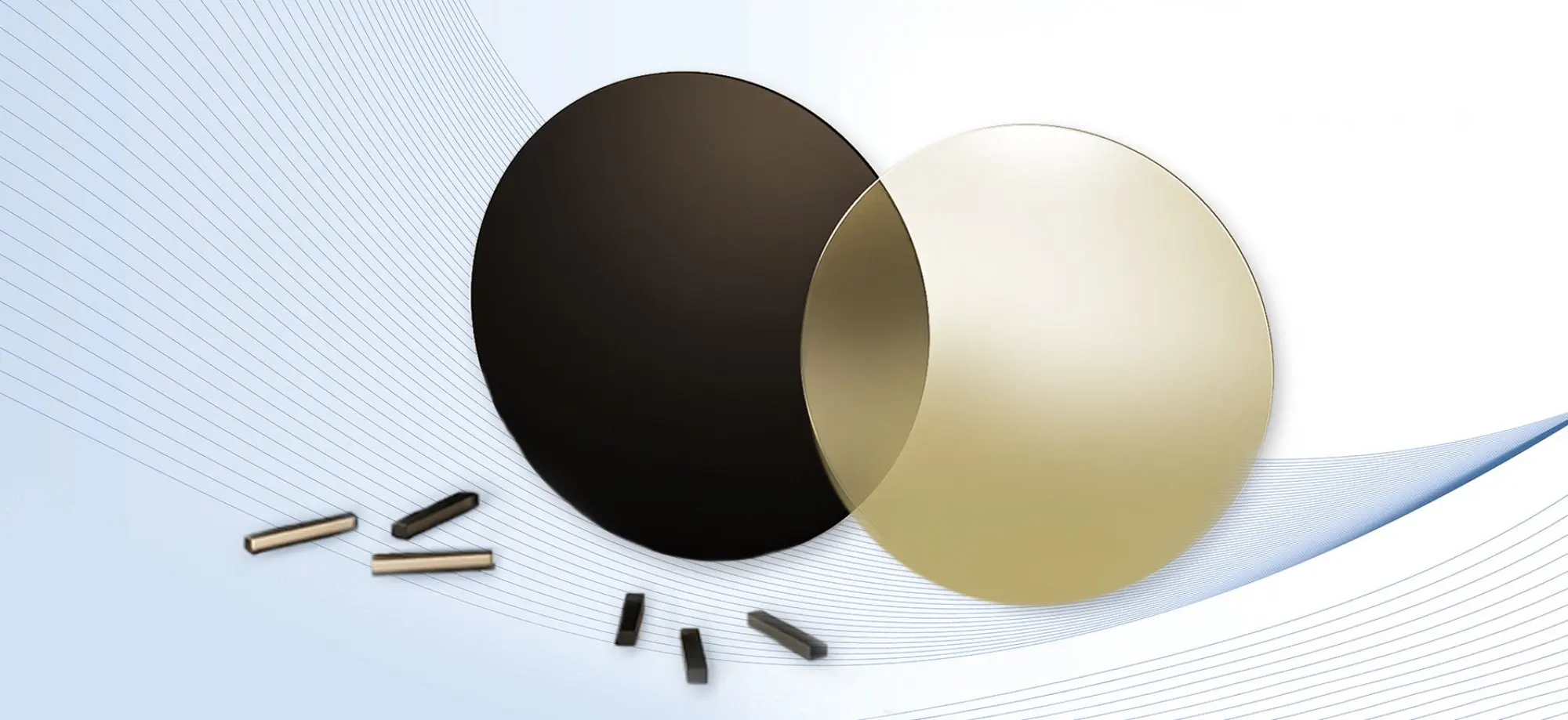

Blanks of synthetic diamond; diamond heat sinks,

tweeter domes and die blanks

WORLDIA provides innovative tooling solutions for traditional as well as E-Mobility. Besides single PCD and PCBN tools, our Engineering team develops complete tooling packages based on the experience with leading vehicle and component manufacturers.

Solid carbide cutting tools play a pivotal role in aerospace manufacturing, offering unparalleled precision and durability. These tools excel in machining aerospace-grade materials such as titanium alloys and carbon fiber composites.And their exceptional hardness and heat resistance ensure consistent performance even under extreme conditions, vital for fabricating critical components like aircraft frames, engine parts, and landing gear.

Furthermore, solid carbide tools enable the creation of intricate designs and tight tolerances, which are essential in aerospace applications where safety and reliability are paramount. Their versatility and dependability make them indispensable for streamlining production processes and upholding the high standards demanded by the aerospace industry.

Our PCBN turning inserts are suitable for the processing of hardened steel, cast iron and powder metallurgy. They have the characteristics of high precision, leanness and constant quality. They are widely used in the processing of gears, bearings and other parts in the fields of automotive parts, wind power and energy.

BDD electrodes can effectively degrade pollutants in various types of organic wastewater, such as pharmaceuticals, pesticides and chemicals, PCB integrated circuit boards, photovoltaic silicon devices, petrochemicals, coking, smelting, printing and dyeing, papermaking, tanning, explosives, wine making, landfill leachate, etc. organic wastewater from the field.

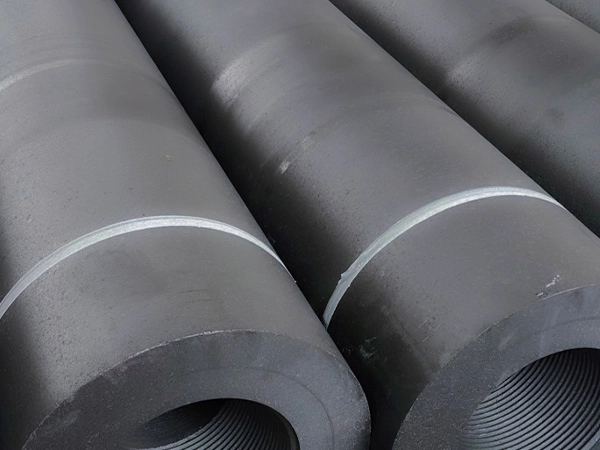

Graphite electrodes are vital components in electric arc furnaces for steelmaking and various industrial processes. Their development focuses on enhancing conductivity, durability, and purity to withstand extreme conditions. As industries evolve, graphite electrodes play a crucial role in achieving efficient and sustainable manufacturing practices, driving innovation and progress.

Solid carbide cutting tools are essential for machining graphite electrodes used in electric arc furnaces for steelmaking. Their exceptional hardness and wear resistance enable precise shaping of electrodes, ensuring optimal furnace performance. These tools enhance productivity and cost-effectiveness in electrode manufacturing, supporting various industrial applications.

We provide highly reliable products and unique solutions through advanced technology and our dedicated team.

● Infrared, green, UV lasers

● Cutting

● Shaping

● CVD coating

● PCD coating

● Diamond coating

● PCD/MCD/CVDD Superhard Tools

● PCBN Superhard Tools

● Ultra-High precision Superhard Tools

● Industrial mono and polycrystalline CVD diamond

● Consumer CVD diamond (Jewelery)

● Scientific research

● Ultrathin (0,05 mm) diamond blanks

● ±1 µm accuracy

● Double-sided polishing

● Laser cutting machines

● Laser grinding machines

● CVD reactors

● Laser engraving machines

● Mirror Polishing machines

● Auxiliary Equipment

One of first 25 companies listed inChina Star Stock Market in 2019

11 wholly-owned legal entities with overall USD 122 million registered capital, USD 512 million market capitalization

Globally 1400 employees

Mit nur einem Klick gelangen Sie zum nächsten Thema.