Focus on Micro-machining—— Worlida PCD Micro Drills |

INTRODUCTION |

|

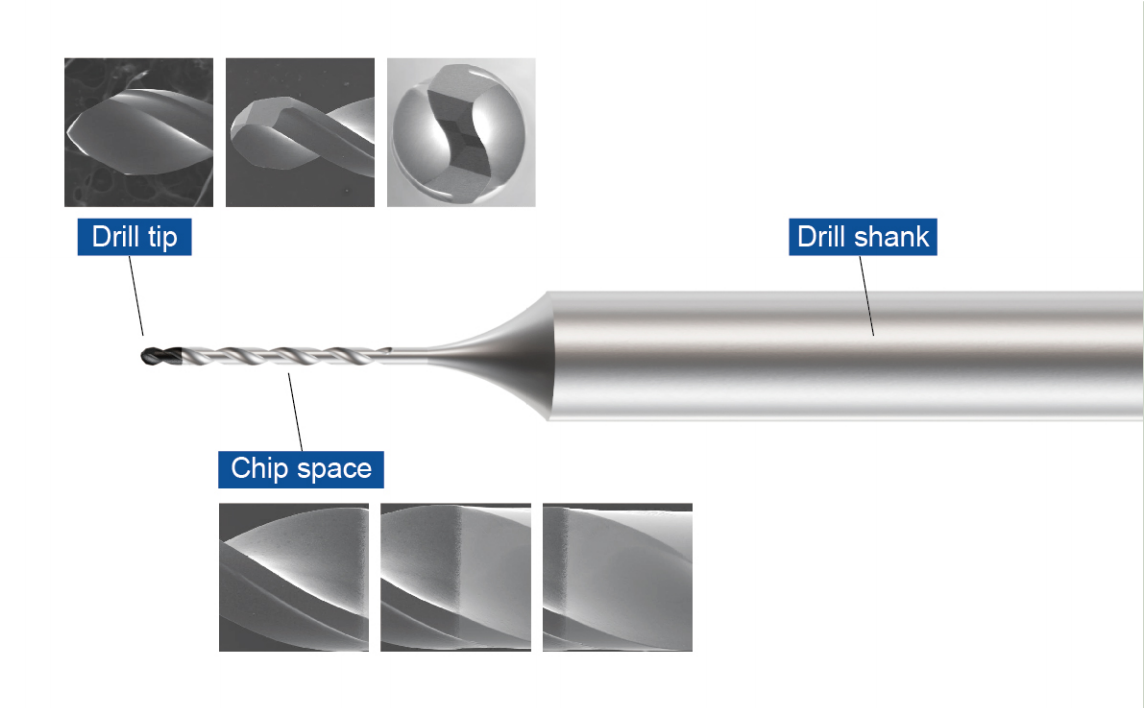

Drilling is a crucial process in machining. In contrast, when machining small holes with a diameter of 0.1mm to 3 mm, traditional methods often face challenges such as difficulty in chip removal, low cooling, short drill life, poor hole wall surface finish, and even defects such as hole edge collapse, cracks, and burrs when dealing with high hardness and wear-resistant materials such as quartz, monocrystalline silicon, polycrystalline silicon, ceramics, and titanium alloys. Consequently, drill bits and drill tips must be designed to meet extremely high processing demands. Following in-depth research and precision design, Worldia has successfully developed and produced a series of diamond (PCD) micro drill tools. Diamond is known for its hardness, wear resistance, and excellent thermal conductivity, which makes it an ideal material for removing chips, cooling, and extending tool life. At the same time, the precision drill tip design ensures the surface finish of the hole wall and the integrity of the orifice, greatly reducing the probability of defects such as edge collapse, cracks, and burrs. |

APPLICATION |

|

Worldia PCD micro drill series are commonly used in the semiconductor, aerospace, 3C industry, chips, and medical devices sectors. |

|

FEATURES and ADVANTAGES |

|

Significant advantages of Worldia Diamond (PCD) micro drills:

|

|

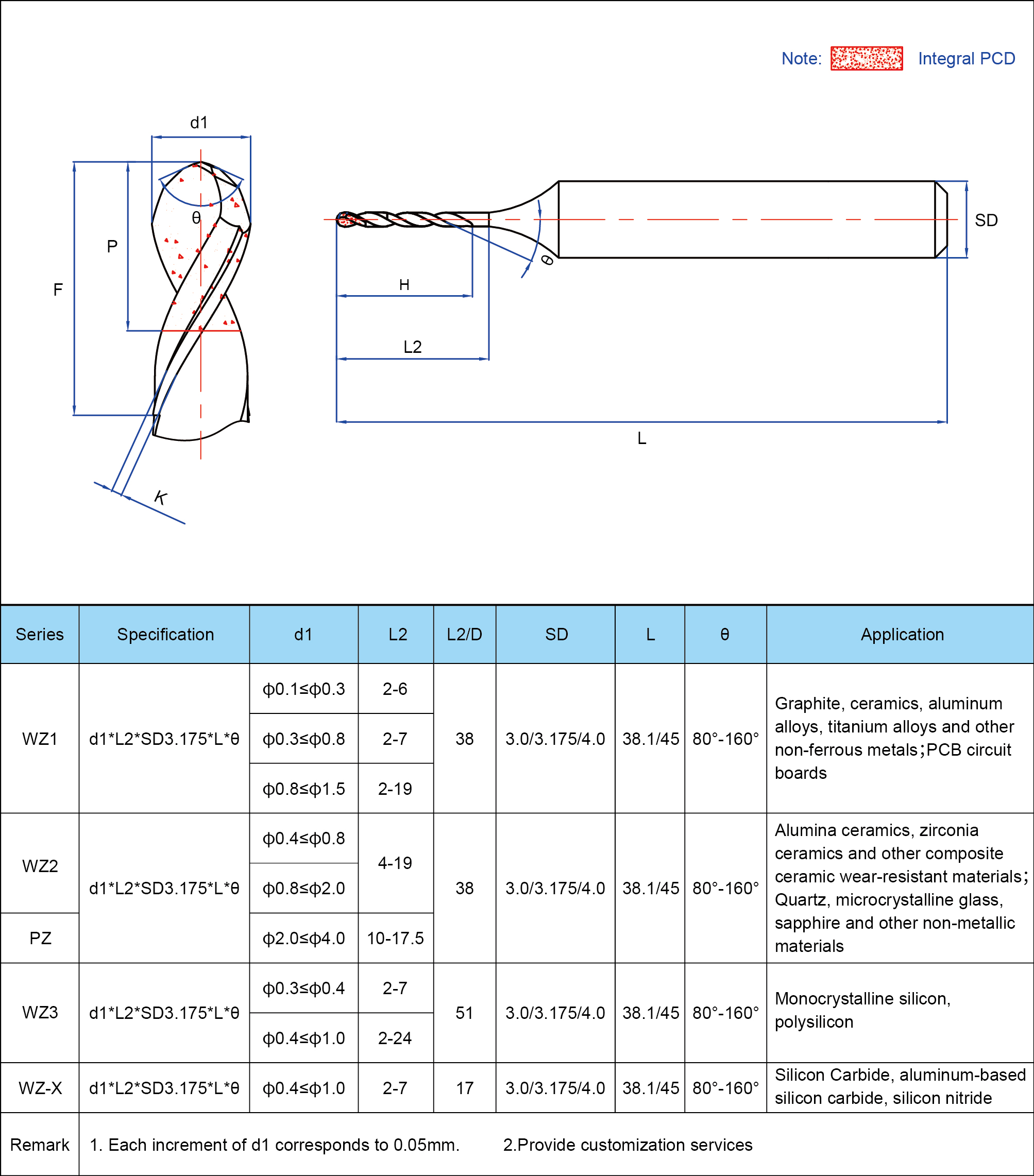

SPECIFICATION |

|

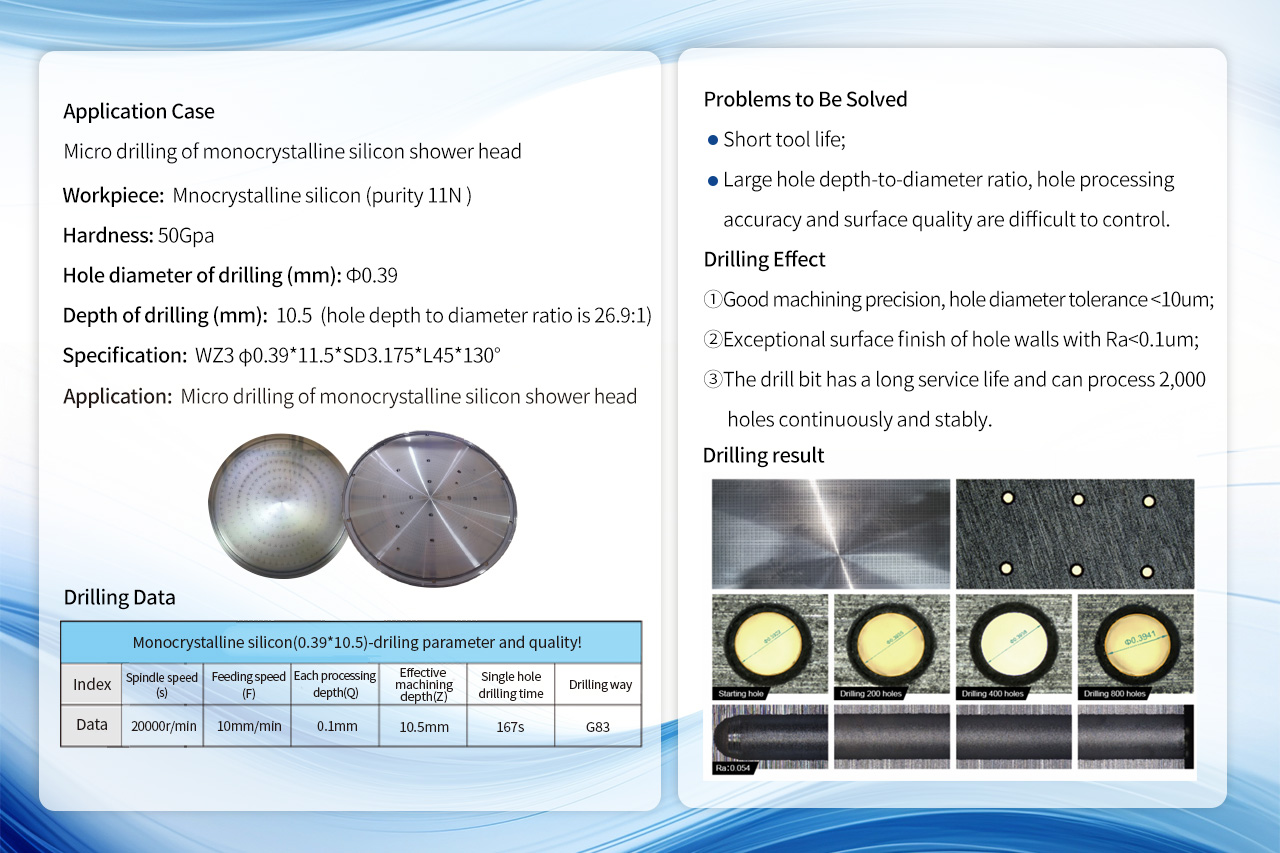

APPLICATION CASE |

|

|

Follow Worldia for the latest trends and news on cutting tools! We're here to keep you informed and inspired. |