| Application: | Non-ferrous machining |

| Tool Type: | Turning insert |

| Brand: | Worldia |

| Availability: | Production time:14 days |

APPLICATIONS |

| CVD diamond has the advantage of high hardness,strong wear resistance and strong stability.Compared to PCD tools,the working life of CVD tools is several times better than PCD tools e.g.the finishing of aluminum, copper, tungsten alloy and other non-metal parts in automobile parts and other industries. By using of CVD diamond tools, high efficiency machining of hard materials can be achieved such as glassfibre reinforced plastics,high-silicon aluminum alloy.Bond-free makes CVD diamond tools suit for machining corrosion materials with high speed and long service life. The polished CVD diamond has excellent finish and low friction coefficient which can reduce the cutting force and friction heat that greatly release high chip load on the cutting edge. |

PRODUCT USAGE |

| CVD diamond(CVDD) introduction |

| P | |

| M | |

| K | |

| N | ● |

| S | |

| H | |

| Material | CVDD |

MATERIAL INTRODUCTION |

| Material | Grain size | Features | Application |

| CVDD | - | CVDD is a pure carbon material without binder with extreme abrasion resistance and good thermal suitability.Due to its perfect cutting edge suitable fro appications where mirror finishes are required. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

SPECIFICATIONS |

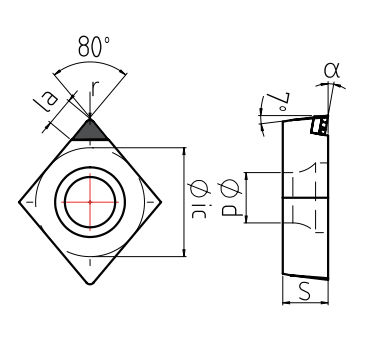

| ic | φd | s | α | re | la | ||||

| ISO catalog number | ANSI catalog number | Tip Shape | CVDD | mm | mm | mm | Degree | mm | mm |

| CCGW060202-1N P00P07 | CCGW2(1.5)(0.5)-1N P00P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 0° | 0.2 | 2.5 |

| CCGT060202-1N P05P07 | CCGT2(1.5)(0.5)-1N P05P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 5° | 0.2 | 2.5 |

| CCGT060202-1N P10P07 | CCGT2(1.5)(0.5)-1N P10P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 10° | 0.2 | 2.5 |

| CCGW060204-1N P00P07 | CCGW2(1.5)1-1N P00P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 0° | 0.4 | 2.5 |

| CCGT060204-1N P05P07 | CCGT2(1.5)1-1N P05P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 5° | 0.4 | 2.5 |

| CCGT060204-1N P10P07 | CCGT2(1.5)1-1N P10P07 | SLST25S | ● | 6.35 | 2.8 | 2.38 | 10° | 0.4 | 2.5 |

| CCGW09T302-1N P00P07 | CCGW3(2.5)(0.5)-1N P00P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 0° | 0.2 | 2.5 |

| CCGT09T302-1N P05P07 | CCGT3(2.5)(0.5)-1N P05P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 5° | 0.2 | 2.5 |

| CCGT09T302-1N P10P07 | CCGT3(2.5)(0.5)-1N P10P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 10° | 0.2 | 2.5 |

| CCGW09T304-1N P00P07 | CCGW3(2.5)1-1N P00P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 0° | 0.4 | 2.5 |

| CCGT09T304-1N P05P07 | CCGT3(2.5)1-1N P05P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 5° | 0.4 | 2.5 |

| CCGT09T304-1N P10P07 | CCGT3(2.5)1-1N P10P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 10° | 0.4 | 2.5 |

| CCGW09T308-1N P00P07 | CCGW3(2.5)2-1N P00P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 0° | 0.8 | 2.5 |

| CCGT09T308-1N P05P07 | CCGT3(2.5)2-1N P05P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 5° | 0.8 | 2.5 |

| CCGT09T308-1N P10P07 | CCGT3(2.5)2-1N P10P07 | SLST25S | ● | 9.525 | 4.4 | 3.97 | 10° | 0.8 | 2.5 |

| CCGW120402-1N P00P07 | CCGW43(0.5)-1N P00P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 0° | 0.2 | 2.5 |

| CCGT120402-1N P05P07 | CCGT43(0.5)-1N P05P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 5° | 0.2 | 2.5 |

| CCGT120402-1N P10P07 | CCGT43(0.5)-1N P10P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 10° | 0.2 | 2.5 |

| CCGW120404-1N P00P07 | CCGW431-1N P00P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 0° | 0.4 | 2.5 |

| CCGT120404-1N P05P07 | CCGT431-1N P05P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 5° | 0.4 | 2.5 |

| CCGT120404-1N P10P07 | CCGT431-1N P10P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 10° | 0.4 | 2.5 |

| CCGW120408-1N P00P07 | CCGW432-1N P00P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 0° | 0.8 | 2.5 |

| CCGT120408-1N P05P07 | CCGT432-1N P05P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 5° | 0.8 | 2.5 |

| CCGT120408-1N P10P07 | CCGT432-1N P10P07 | SLST25S | ● | 12.7 | 5.5 | 4.76 | 10° | 0.8 | 2.5 |