| Application: | Non-ferrous material |

| Tool Type: | cutomized |

| Brand: | Supower |

| Availability: | production time:7 days |

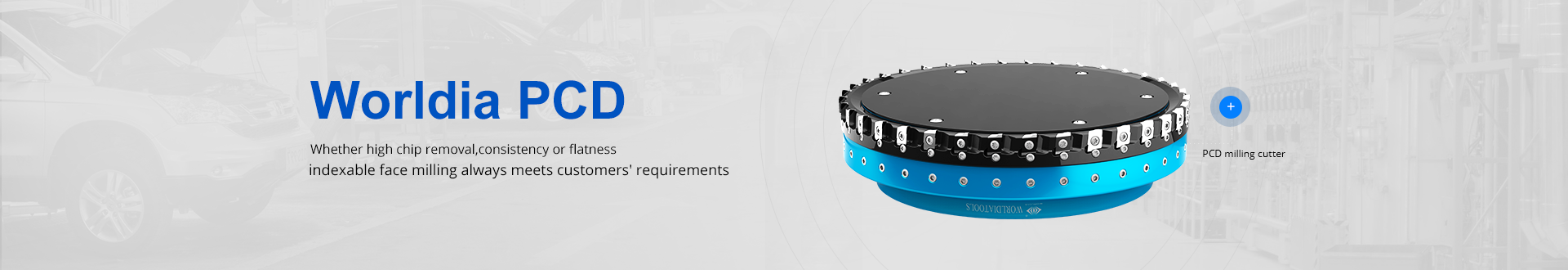

APPLICATIONS |

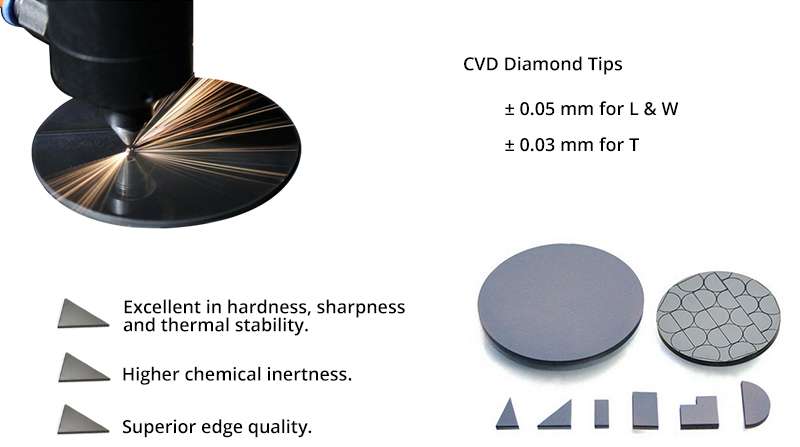

| With the rapid development of the manufacturing industry, new technologies such as high-speed machining, dry machining and turning instead of grinding emerge continuously, which put forward higher requirements to the performance of cutting tools. Based on this, CVD diamond turns out to be an ideal solution for cutting tool applications, especially in continuous and finish machining. |

PRODUCT USAGE |

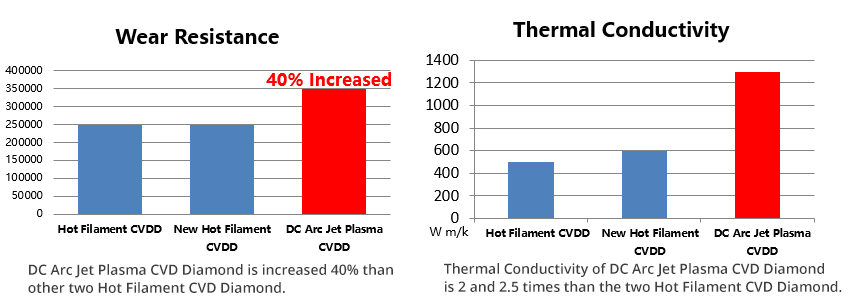

| Now we have three types CVD Diamonds(CVDD).

They are Hot Filament CVD Diamond(CVDH), NEW Hot Filament CVD Diamond(CVDN) and DC Arc Jet Plasma CVD Diamond(CVDJ). |

| P | |||

| M | |||

| K | |||

| N | ● | ● | ● |

| S | |||

| H | |||

| Material | CVDH | CVDN | CVDJ |

MATERIAL INTRODUCTION

|

|||||||

| Material Introduction | Features | Application | |||||

| CVD Diamond | CVDD is a pure carbon material without binder with extreme abrasion resistance and good thermal suitability.Due to its perfect cutting edge suitable fro appications where mirror finishes are required. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. | |||||

PRODUCTION INFOMATION |

|||||||

| Dimension(Max) | Thickness | Blank | Tip | Dresser | |||

| Item | Color | mm | mm | μm | μm | μm | Finish |

| CVDH | Black | 25.4*25.4 | 0.3-1.3 | ±20/±50 | ±20/±50 | ±20/±50 |

Single Lap

Double Lap Single Polish

Double Polish

|

| CVDN | Black | 25.4*25.4 | 0.25-1.0 | ±20/±50 | ±20/±50 | ±20/±50 | |

| CVDJ | Semi Transparency | 70 | 0.5-1.3 | ±20/±50 | ±20/±50 | ±20/±50 | |

|

COMPARISON |

|||||||

|

|||||||

CLASSIFICATION |

|||||||

| Item | Picture |

Dresser Application |

Cutting Application |

Thermal Application |

|||

| CVDH |  |

★★★★ |

★★★★ |

★★★ |

|||

| CVDN |  |

★★★ |

★★★★★ |

★★★★ |

|||

| CVDJ |  |

★★★★★ |

★★★★ |

★★★★★ |

|||

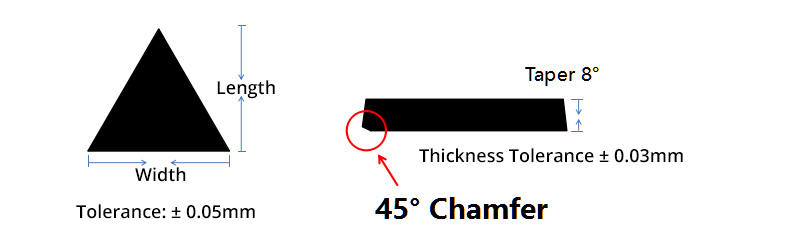

SPECIFICATIONS We can supply cutting tips in three different CVD Diamonds and provide customized service per your request. |

| Chamfer service on pocket side as shown on the picture, which is helpful for brazing it to tool pocket completely. Taper 8 degree, our normal tolerance ±30μm, max. tolerance is ±20μm. |